Project purpose and goals

Background and incitements

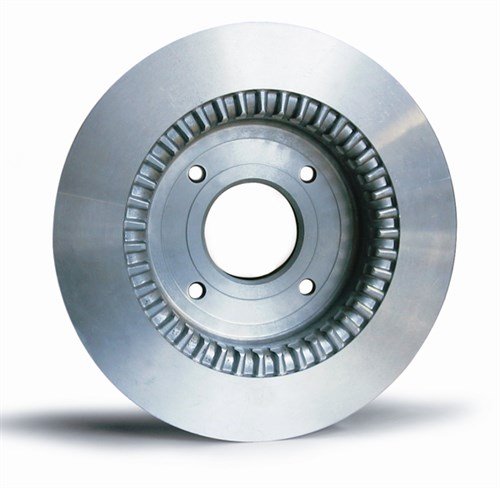

The use of lightweight materials in the vehicle industry is an important approach to reduce the carbon footprint. Not only does the substitution of these materials result in lighter, and therefore, less fuel-consuming vehicles, but can also offer a possibility to use materials produced from more environmentally sustainable processes and allow high level recycling. For successful implementation of electric vehicles this is even more important due to the extra weight introduced by batteries. However, all new materials, material combinations, and joint configurations need to pass numerous tests to ensure product durability and safety. One of the more critical tests investigates the atmospheric corrosion resistance of the material.

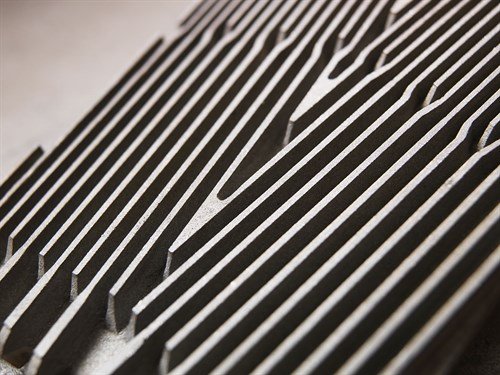

Today, the most commonly used methods for evaluating corrosion of materials is testing by cyclic variation of relative humidity and/or temperature together with intermittent salt spray in so called accelerated corrosion tests (ACT) in climate chambers. Common problems with these types of test are related to robustness, which manifests as lack of repeatability and reproducibility for basic corrosion modes on materials [2] and the long testing time (usually weeks or months). The introduction of new lightweight multi-materials will therefore put an increased demand on the corrosion assessment to be more reliable and efficient.

The method we propose to improve the corrosion testing – and prediction methods - is to combine the experimental testing with atmospheric corrosion models. In contrast to other parts of the automotive production process (e.g.. aerodynamic properties, strength, etc), little has so been done to incorporate models into the forecasting of corrosion.

Programme relevance

The project aims to reduce the development time for new lightweight alloy-combinations in vehicle components by using computational models to assist corrosion testing. The corrosion testing is an essential part of the development before introduction of new material solutions. Modelling of corrosion processes, including galvanic corrosion, is therefore of large interest in order to support the product technology and manufacturing planning process by technical simulations.

The project supports the Swedish lightweight agenda (Lättvikt lyfter svensk konkurrenskraft – för en mer hållbar värld) to produce lighter products, components and materials in Swedish vehicle industry and increases competitiveness and sustainability. The project goals are in line with the objectives of innovation theme 2 – Lighter with shorter development time, which target 50% reduction in product weight without the development time delaying the market introduction of new lightweight solutions.

More specifically, the project contributes to the purpose of this call (2.2) by developing lightweight solutions for the automotive industry. Even if the aviation industry and infrastructure sector are not represented in the project, the developed tools can be used also for these sectors. Corrosion testing is an essential part in aviation, and the infrastructure road environments (bridges, tunnels) are areas experiencing the same type of conditions as vehicles. Increased use of aluminium will put in both these sectors a demand on more efficient and simulation assisted corrosion testing.

Gender issues have been considered when forming the project management group (3 females – 5 males), where a female from the industry has been selected as chair.

Objectives

The objectives of the project are to:

• Enable faster and more accurate corrosion test-methods, both applicable in accelerated tests as well as on mobile vehicle tests, especially for multi-material components with one material being an aluminium alloy.

• Introduce validated virtual corrosion-models as an aid for more rapid and robust product development with mixed metals.

• Enable lighter, more weight optimised designs by improved corrosion prediction and anti-corrosion design.

Corrosion modelling can contribute strongly to standard testing, by enabling calculation of transfer functions between field environments and accelerated test conditions for different material systems. This is based on the premise that basic first principle thermodynamic and kinetic constants are known or can be determined for the systems. Knowing such basic parameters, the behaviour of a system can also be recalculated to conditions outside the actual test range. Based on a limited set of exposure evaluations in time with aid of modelling, it is then possible to make more accurate projections to long-time in-service behaviour.

These scientific objectives will contribute to the increase of Swedish capacity for research and innovation, thereby ensuring competitiveness and jobs in the field of vehicle industry. In addition, the project promotes cooperation between OEMs, universities, and higher education institutions.

The overall focus is on reducing the development time for new lightweight multi-material products (innovation theme 2) by creating more reliable and time-saving corrosion prediction ("lighter with shorter development time”). The virtual corrosion models are expected to be integrated into the decision of suitable cycling schemes and configurations for new material combinations. Virtual tools are specifically mentioned in innovation theme 2 as a desired method for faster market introduction of new materials.

Results

The main deliverables from the project will be:

• Standardised sample configurations suitable for addressing primarily galvanic corrosion to be used in accelerated testing and modelling. This will also result in a common proposal for an ISO standard.

• A modelling interface for rapid assessment of multi-material interactions that can be used internally by partners after the project.

• Methods yielding comparable results on galvanic corrosion of multi-material components from vehicle tests, accelerated tests, electrochemical measurements, and computer simulations of multi-material systems.

• Assessment of service life failure modes by computer simulations for different scaling factors (for example the effect of salt concentration, salt composition, temperature and geometry).

• New protocols for achieving more robust accelerated tests.

Originality and newsworthiness

The possibility to model important processes in accelerated corrosion testing has earlier been demonstrated and is described in section 2. The defining and novel features of this proposed project, which also will find direct industrial use, is the strive not only to simulate existing accelerated corrosion tests and to use the results for developing more robust tests and design success prediction, but also to make sure that developed methodology has the possibility to gain general acceptance worldwide. This is made possible through the unique competence in a combination of critical fields including but not limited to:

• state of the art international competence in development of accelerated corrosion tests

• state of the art international competence in atmospheric corrosion modelling

• state of the art international competence in experimental studies of atmospheric corrosion

• active participation and leadership in ISO standardisation of accelerated corrosion tests.

Adding the vehicle design and testing competences among participants, the project consortium is a unique hub for new technologies development in the area.

Deltagande företag

RISE (f.d Swerea KIMAB)

Gestamp Sweden AB

Scania CV

Volvo Personvagnar