LIGHTSPAN project optimizes design & manufacturing of pedestrian and bicycle bridges for a sustainable future

During the Steel Construction Day at Älvsjö Fair in October, the members of the LIGHTSPAN project, Peter Nilsson Strand, Amer Ali and Annette Fjeld-Hansen, presented the role of GA optimization and robotic welding in designing and manufacturing sustainable pedestrian and bicycle bridges.

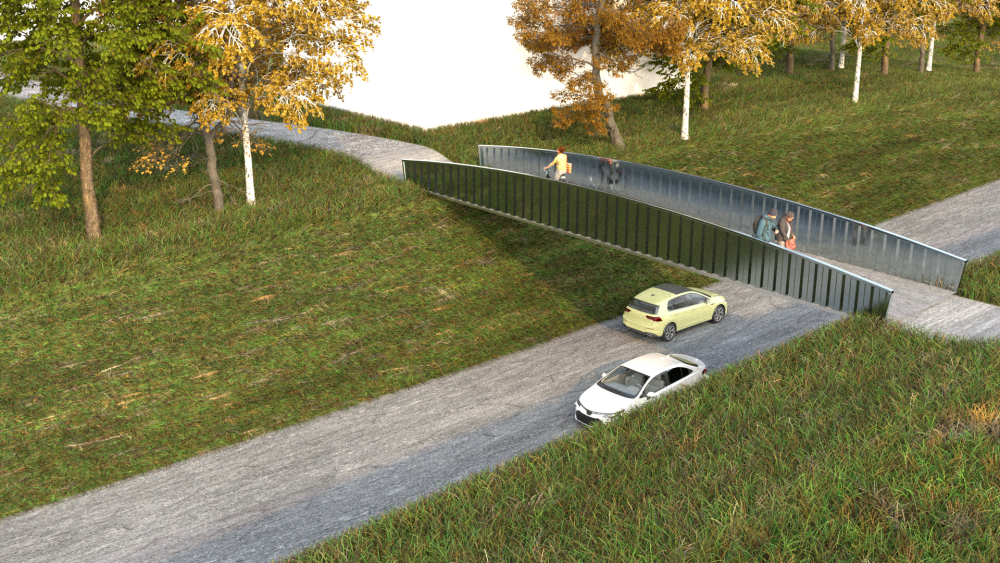

Rundquist Arkitekter designed the LIGHTSPAN bridge concept shown here.

Peter Nilsson-Strand explained the background and objectives of the LIGHTSPAN project. Amer Ali from WSP presented results from GA optimization, which enables both material and cost savings, and Anette Fjeld-Hansen from Prodtex talked about the possibilities of robotic welding for bridge construction.

Funded by LIGHTer and starting in December 2020, the LIGHTSPAN project has been dedicated to optimizing the design and manufacturing of pedestrian and cycle bridges (GC bridges). The aim has been to create bridges that are not only technically sustainable, but also environmentally friendly and cost-effective. By automating the production process, including assembly and surface treatment, the project has opened the door to new solutions. Several material options have been evaluated, including conventional structural steel, weatherproof steel, duplex steel and aluminum.

Various truss structures, which form the primary load-bearing system for GC bridges, have been evaluated. Using generic optimization algorithms, different bar cross-sections and geometries have been investigated to find the most environmentally friendly and economically viable options. Up to about 20% material savings can be achieved when GA algorithms are used in the early design stage.

New concepts that are scalable and more adapted to robotic manufacturing have also been developed and evaluated. These achieve significant weight and cost savings, about 20-30%, and more efficient manufacturing.

The LIGHTSPAN project has brought together a range of partners, including workshops, designers, architects, material manufacturers, bridge owners and research institutes. The project has run for three years and will end in November 2023.