With the continuously increasing power density, electronics generate enormous heat during operation. Effective cooling systems are thereby indispensable in a wide variety of household and industrial applications of electronics. Aluminum is an excellent material for thermal management because of its favorable combination of high thermal conductivity, light weight, low cost, and high strength-to-weight ratio. In particular, its low melting point facilitates many processing techniques to fabricate versatile components in cooling systems with high-level shape complexity and dimensional capability.

Recently, great efforts are being made to further improve the thermal conductivity and reduce the mass density of aluminum for more demanding applications. The predominant techniques include aluminum matrix composites (AMCs) and aluminum metal foams. However, it is challenging for these techniques to simultaneously reduce the weight of aluminum components, retain or even improve their thermal performance, and maintain the easy processing merit.

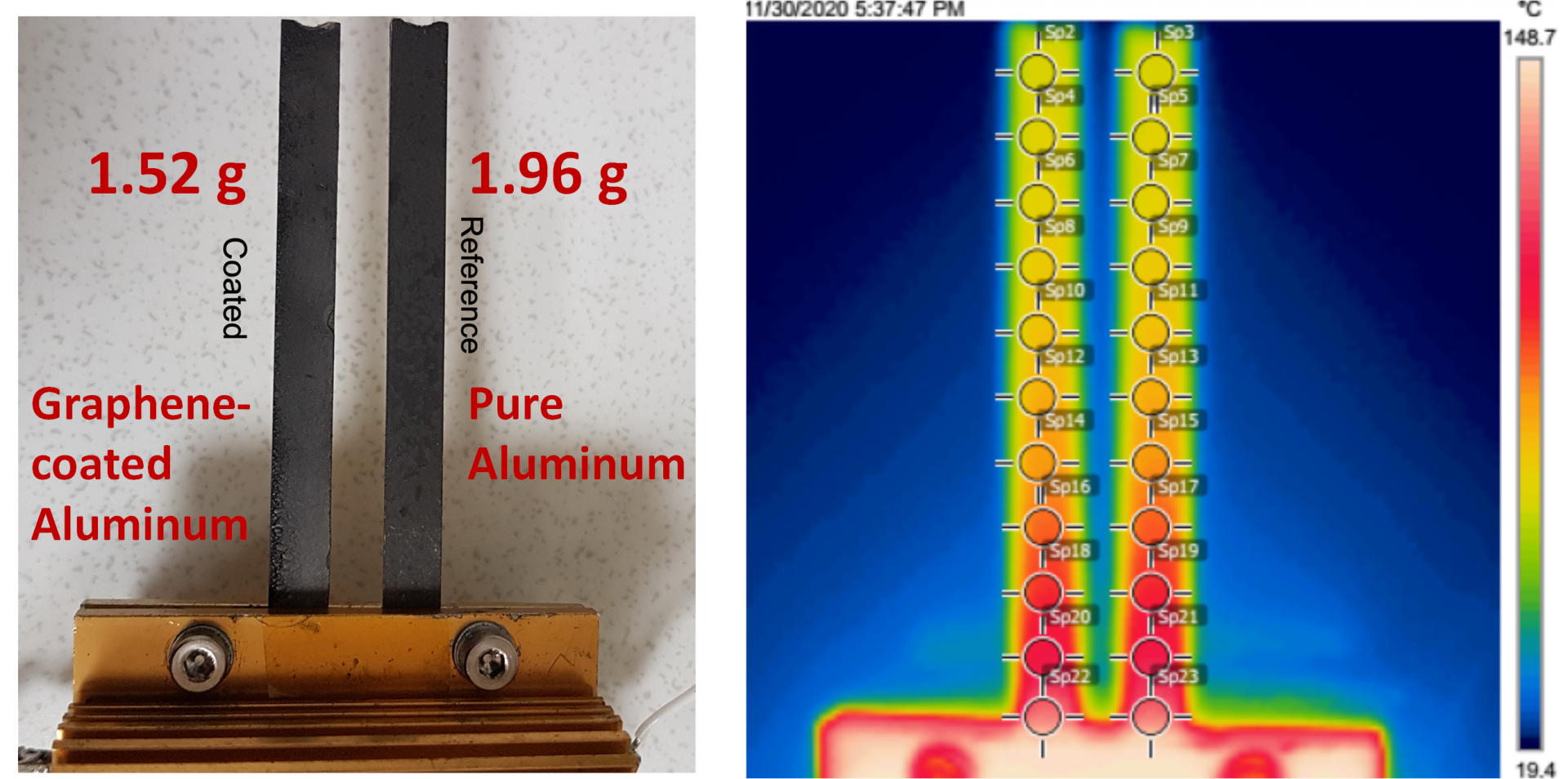

Our long-term research is to use thick graphene coatings on thinned aluminum components to replace a part of aluminum, so as to reduce the weight and meanwhile retain/improve the thermal performance of original (pure) aluminum components. The enabling factor relies on the high performance of graphene, theoretically at least 5 times more thermal conductive and 30% lighter than aluminum. In particular, the coating process is at low temperature (much lower than the melting point of aluminum) so as to avoid the interfacial reactions between aluminum and carbon which can hardly be avoided in the AMC methods. Moreover, the coating process does not require any change of materials or processing in the present fabrication so that the easy processing merit of aluminum can be retained and no extra time is needed to develop the application in using the lightweight solutions.