Kort sammanfattning av projektidén

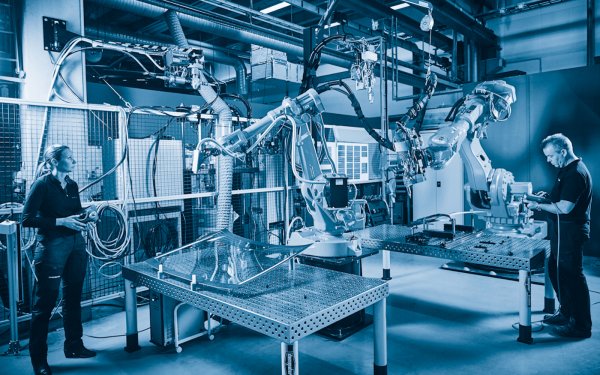

ALL-LIGHT focuses on the development of high strength aluminium (Al) alloys for additive manufacturing (AM) coupled with weight optimized design for AM of components used in aerospace and industrial applications. ALL-LIGHT new approach aims to enhance Al AM production in its entirety, starting from the based material, the powder, continuing with choosing the relevant parameters for the process and the post treatment and finishing with design optimization for AM. This should lead to the production of high strength aluminium demonstrators, to the qualification of a new Al grade for AM and, after a qualification of performance for the Al AM components to the development of a standard component for Al AM.

Projektets bidrag till våra programmål

ALL-LIGHT addresses an industrial need of having high strength Al alloys for AM to step in performance compared to steel or mainstream AM Al-Mg-Si alloy. The projects results will respond to the innovation’s themes 2 “lighter with a shorter development time” and 4 “lighter with improved properties” and will cover TRL 3 to 5. This will be verified through the manufacturing of lightweight demonstrators, chosen with the industrial partners but also with the conception and manufacturing of specific test builds for the qualification of performances. Others results of ALL-LIGHT will be spreading knowledge on Al AM generic design characteristics and starting to work on the standardization of Al AM components. If ALL-LIGHT is successful, it will then strengthen all the skills chain from academics to SME and end-users companies (innovation mechanism 5) and by consequence improve the Swedish competitiveness in lightweight technologies. A final goal will be for the industrial partners to find commercial applications of Al AM components within five years with the support of the consortium.

Projektets implementering

ALL-Light will take advantage of an actors’ constellation designed for developing high strength Al alloys and building lighter Al AM components. Indeed, AM starts with powders for which recognized partners such as Chalmers, Swerea IVF and Höganäs, a worldwide known powder company, are involved. We aim also to optimize the AM process, design and post-treatments of printed elements. For this, ALL-LIGHT will benefit from experts at Swerea IVF, Chalmers but also AGA gas, a gas technology leader in Scandinavia, Quintus Technologies, world leader in high pressure technology and AMEXCI, a Swedish SME whose goal is to accelerate adoption of AM in industries. Finally, Swedish Al end-user companies for demanding applications, such as SAAB and ABB, will set the specification for the components which will help to build standardized test builds with the SIS (Swedish Standards Institute).

Deltagande företag

RISE IVF (Swerea IVF)

Chalmers Tekniska Högskola AB

AMEXCI AB

AGA Gas AB

Quintus Technologies AB

Höganäs AB

SIS, Swedish Standards Institute