Funding in this project is from Vinnova, through the SIP LIGHTers big call 2020.

Ultralightweight Coatings for Electrically Conductive Textile

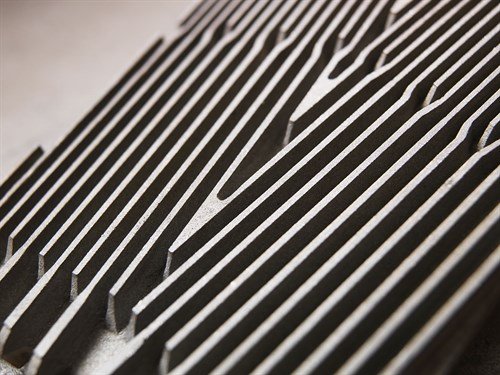

Electrically conductive fibres are of great importance for such industries as aerospace, transport, energy, and national defence. The weight of the electrically conductive material is crucial for the performance of systems components and elements. Traditionally, metals are well-known conductors, but they are heavy, stiff and corrosion sensitive; while carbon materials can provide superior conductivity, lightweight, strength and chemical stability. Carbon nanotubes or graphene flakes are the lightest candidates for conductive coatings. However, they are highly dispersible and must be used with a binder – which brings additional weight. Graphene as a material is also expensive and still possess severe material quality issues.

Grafren AB has developed a process for binder-free coating of graphene which results in creation of ultralightweight conductive textile: only 3 (three!) grammes of graphene per square meter of fibre-based textile provides resistance as low as 100 Ohm/□. Such an ultralight weight design became possible due to use of extra thin flakes of graphene and the innovative method coating of every single fibre of the textile - on the nanointegration level, which no other methods (inkjet, screen printing, dry-pad or aerosol painting) can provide. The aim of this study is therefore to analyse the relevant market needs, verify the potential of solution for the identified applications and accumulate the necessary partners and resources for the future R&D project